Alignment & Vibration

EDDYTHERM Portable

PRUFTECHNIK not only supplies premium alignment systems for aligning machines and shafts, but also the right induction heating tools for mounting bearings on shafts. The benefits of induction heating include safety, efficiency, and overall energy savings.

EDDYTHERM Portable can be used for all bearings and work pieces with an inner diameter of min. 20 mm (0.78 inches) and a weight of up to 10 kg (22 lbs). The maximum induction heat is 180°C (356°F), protecting your bearings against overheating and damage. The workpiece is placed onto the cone shaped heating surface. The integrated time and temperature regulation capability ensures that the workpiece is heated evenly with no risk of overheating.

How does induction heating work? In just a few minutes, the bearings are preheated by induction so that that they expand and glide effortlessly onto the shaft. When the bearing cools down, it assumes its original size and thus guarantees the desired tight fit on the shaft. Due to the induction heat, all tolerances and material properties are maintained without loss. No further work steps are necessary. EDDYTHERM Portable is a safe induction heating tool that only heats the work piece, not the tool itself.

EDDYTHERM Portable can be used for all bearings and work pieces with an inner diameter of min. 20 mm (0.78 inches) and a weight of up to 10 kg (22 lbs). The maximum induction heat is 180°C (356°F), protecting your bearings against overheating and damage. The workpiece is placed onto the cone shaped heating surface. The integrated time and temperature regulation capability ensures that the workpiece is heated evenly with no risk of overheating.

How does induction heating work? In just a few minutes, the bearings are preheated by induction so that that they expand and glide effortlessly onto the shaft. When the bearing cools down, it assumes its original size and thus guarantees the desired tight fit on the shaft. Due to the induction heat, all tolerances and material properties are maintained without loss. No further work steps are necessary. EDDYTHERM Portable is a safe induction heating tool that only heats the work piece, not the tool itself.

Download

Product Lainnya

Fluke 805 Vibration Meter

• Reliable, repeatable, accurate device for checking bearings and overall vibration

• Features innovative sensor design that minimizes measurement variations caused by device angle or contact pressure

• Provides consistent data quality at both low and high frequency ranges

• Offers four-level severity scale to assess urgency of problems and bearing condition

• Features innovative sensor design that minimizes measurement variations caused by device angle or contact pressure

• Provides consistent data quality at both low and high frequency ranges

• Offers four-level severity scale to assess urgency of problems and bearing condition

VIBSCANNER 2 EX

The new VibScanner 2 Ex is a next-generation, explosion protection system for quickly detecting machine vibration in hazardous work environments. Measuring simultaneously on three axes, the VibScanner 2 Ex sets the benchmark for fast and accurate measurements of machine, gear, and bearing issues.

This is the ultimate tool for fast and accurate machine vibration measurements. The VibScanner 2 Ex heightens efficiency and data quality. In just a quarter of the time of a standard data-collector, it precisely measures available data in three axes. Equipped with a triaxial sensor, it requires only one measurement point and the click of a button to begin collecting machine data.

This device is ideal for route-based maintenance jobs in environments where explosion protection standards are required. Its rugged magnetic foot of the triaxial sensor fits perfectly on the housing of any motor, pump, fan, or other rotating device, detecting vibration right near the source.

The VibScanner 2 Ex will diminish worries about finding the right measurement points at the machine. Because it features a Prüftechnik triaxial sensor, just one measurement point is required instead of three separate ones. This saves considerable time without sacrificing data quality. The “Triax-Effect” enables users to obtain measurements up to four times faster than the industry standard while achieving new levels of data quality.

ones. VibScanner 2 Ex thus saves considerable time without sacrificing data quality. The “Triax-Effect” enables obtaining measurements up to four times faster than the industry standard while achieving new levels of data quality.

This is the ultimate tool for fast and accurate machine vibration measurements. The VibScanner 2 Ex heightens efficiency and data quality. In just a quarter of the time of a standard data-collector, it precisely measures available data in three axes. Equipped with a triaxial sensor, it requires only one measurement point and the click of a button to begin collecting machine data.

This device is ideal for route-based maintenance jobs in environments where explosion protection standards are required. Its rugged magnetic foot of the triaxial sensor fits perfectly on the housing of any motor, pump, fan, or other rotating device, detecting vibration right near the source.

The VibScanner 2 Ex will diminish worries about finding the right measurement points at the machine. Because it features a Prüftechnik triaxial sensor, just one measurement point is required instead of three separate ones. This saves considerable time without sacrificing data quality. The “Triax-Effect” enables users to obtain measurements up to four times faster than the industry standard while achieving new levels of data quality.

ones. VibScanner 2 Ex thus saves considerable time without sacrificing data quality. The “Triax-Effect” enables obtaining measurements up to four times faster than the industry standard while achieving new levels of data quality.

VIBXPERT II Balancer

Imbalances on rotating drive shafts can be detected and eliminated with the VIBXPERT II balancer.

The smart measuring principle and the powerful computing capacity enable balancing on one or two planes. Various operating modes are available for balancing, so that a perfect result is always achieved.

VIBXPERT II Balancer can be upgraded to a high-performance condition monitoring device VIBXPERT II, including all operating modes for machine condition monitoring.

The smart measuring principle and the powerful computing capacity enable balancing on one or two planes. Various operating modes are available for balancing, so that a perfect result is always achieved.

VIBXPERT II Balancer can be upgraded to a high-performance condition monitoring device VIBXPERT II, including all operating modes for machine condition monitoring.

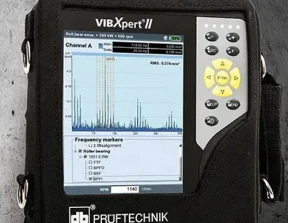

VIBXPERT II

The VIBXPERT II from PRUFTECHNIK is the mobile power package for fast and reliable recording and analysis of machine condition data. After a very short measuring time, the current machine status data is shown on the color display. The maintenance expert can analyze the data on site. From the recorded machine condition data, all values can be read from the various characteristic value modes that are important for an exact machine condition analysis.

The device is used directly on site at the machine, from the machine hall to the diesel generator of an oil tanker or from a bucket excavator to a hydroelectric turbine. The robust design enables both fast and complex interventions. Whether in clinically clean systems, or harsh industrial environments. VIBXPERT II sets the standard in mobile machine and plant condition monitoring.

In addition to reliable, fast, and highly effective data analysis, the VIBXPERT II can also be used for operational balancing. This makes the VIBXPERT II the most powerful and effective device in mobile condition monitoring. VIBXPERT II is compatible with PRUFTECHNIK’s own OMNITREND Center analysis software, enabling highly efficient and precise analysis results. Center analysis software, enabling highly efficient and precise analysis results.

The device is used directly on site at the machine, from the machine hall to the diesel generator of an oil tanker or from a bucket excavator to a hydroelectric turbine. The robust design enables both fast and complex interventions. Whether in clinically clean systems, or harsh industrial environments. VIBXPERT II sets the standard in mobile machine and plant condition monitoring.

In addition to reliable, fast, and highly effective data analysis, the VIBXPERT II can also be used for operational balancing. This makes the VIBXPERT II the most powerful and effective device in mobile condition monitoring. VIBXPERT II is compatible with PRUFTECHNIK’s own OMNITREND Center analysis software, enabling highly efficient and precise analysis results. Center analysis software, enabling highly efficient and precise analysis results.