Alignment & Vibration

VIBSCANNER 2

A unique handheld measuring device with which even untrained personnel can easily and effectively measure machine vibration on rotating machinery. Thanks to its forward-looking measuring principle and data acquisition across three axes with the triaxial sensor, all relevant condition information is recorded with the touch of a single button. And at a measurement speed that opens up fully new dimensions. Not only is the VIBSCANNER 2 a breakthrough in terms of measurement speed and precision, but also through its robustness and its intuitive operating concept.

Depending on the filter settings, it measures overall values, spectra, and time signals synchronously in 3 axes. In combination with a triaxial sensor, VIBSCANNER 2 collects even more machine condition data per measurement location.

• Added value thanks to additional vibration data without affecting the measurement time

• Quick data acquisition thanks to synchronous measurement in 3 axes

• Clear channel assignment without any additional cable adapter

A triaxial sensor measures vibration in 3 perpendicular directions at once, while a single-axis sensoronly measures in one direction at a time. Certain conditions such as cocked bearing or a bent shaft can be identified in a single measurement with a triaxial sensor.

The bottom line: In combination with a triaxial sensor, VIBSCANNER 2 delivers even more comprehensive information per measurement location at the push of a button. This creates an overall image of the machine‘s health without affecting the measuring time.

Depending on the filter settings, it measures overall values, spectra, and time signals synchronously in 3 axes. In combination with a triaxial sensor, VIBSCANNER 2 collects even more machine condition data per measurement location.

• Added value thanks to additional vibration data without affecting the measurement time

• Quick data acquisition thanks to synchronous measurement in 3 axes

• Clear channel assignment without any additional cable adapter

A triaxial sensor measures vibration in 3 perpendicular directions at once, while a single-axis sensoronly measures in one direction at a time. Certain conditions such as cocked bearing or a bent shaft can be identified in a single measurement with a triaxial sensor.

The bottom line: In combination with a triaxial sensor, VIBSCANNER 2 delivers even more comprehensive information per measurement location at the push of a button. This creates an overall image of the machine‘s health without affecting the measuring time.

Download

Produk Lainnya

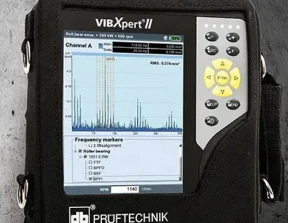

VIBXPERT II

The VIBXPERT II from PRUFTECHNIK is the mobile power package for fast and reliable recording and analysis of machine condition data. After a very short measuring time, the current machine status data is shown on the color display. The maintenance expert can analyze the data on site. From the recorded machine condition data, all values can be read from the various characteristic value modes that are important for an exact machine condition analysis.

The device is used directly on site at the machine, from the machine hall to the diesel generator of an oil tanker or from a bucket excavator to a hydroelectric turbine. The robust design enables both fast and complex interventions. Whether in clinically clean systems, or harsh industrial environments. VIBXPERT II sets the standard in mobile machine and plant condition monitoring.

In addition to reliable, fast, and highly effective data analysis, the VIBXPERT II can also be used for operational balancing. This makes the VIBXPERT II the most powerful and effective device in mobile condition monitoring. VIBXPERT II is compatible with PRUFTECHNIK’s own OMNITREND Center analysis software, enabling highly efficient and precise analysis results. Center analysis software, enabling highly efficient and precise analysis results.

The device is used directly on site at the machine, from the machine hall to the diesel generator of an oil tanker or from a bucket excavator to a hydroelectric turbine. The robust design enables both fast and complex interventions. Whether in clinically clean systems, or harsh industrial environments. VIBXPERT II sets the standard in mobile machine and plant condition monitoring.

In addition to reliable, fast, and highly effective data analysis, the VIBXPERT II can also be used for operational balancing. This makes the VIBXPERT II the most powerful and effective device in mobile condition monitoring. VIBXPERT II is compatible with PRUFTECHNIK’s own OMNITREND Center analysis software, enabling highly efficient and precise analysis results. Center analysis software, enabling highly efficient and precise analysis results.

EDDYTHERM Portable

PRUFTECHNIK not only supplies premium alignment systems for aligning machines and shafts, but also the right induction heating tools for mounting bearings on shafts. The benefits of induction heating include safety, efficiency, and overall energy savings.

EDDYTHERM Portable can be used for all bearings and work pieces with an inner diameter of min. 20 mm (0.78 inches) and a weight of up to 10 kg (22 lbs). The maximum induction heat is 180°C (356°F), protecting your bearings against overheating and damage. The workpiece is placed onto the cone shaped heating surface. The integrated time and temperature regulation capability ensures that the workpiece is heated evenly with no risk of overheating.

How does induction heating work? In just a few minutes, the bearings are preheated by induction so that that they expand and glide effortlessly onto the shaft. When the bearing cools down, it assumes its original size and thus guarantees the desired tight fit on the shaft. Due to the induction heat, all tolerances and material properties are maintained without loss. No further work steps are necessary. EDDYTHERM Portable is a safe induction heating tool that only heats the work piece, not the tool itself.

EDDYTHERM Portable can be used for all bearings and work pieces with an inner diameter of min. 20 mm (0.78 inches) and a weight of up to 10 kg (22 lbs). The maximum induction heat is 180°C (356°F), protecting your bearings against overheating and damage. The workpiece is placed onto the cone shaped heating surface. The integrated time and temperature regulation capability ensures that the workpiece is heated evenly with no risk of overheating.

How does induction heating work? In just a few minutes, the bearings are preheated by induction so that that they expand and glide effortlessly onto the shaft. When the bearing cools down, it assumes its original size and thus guarantees the desired tight fit on the shaft. Due to the induction heat, all tolerances and material properties are maintained without loss. No further work steps are necessary. EDDYTHERM Portable is a safe induction heating tool that only heats the work piece, not the tool itself.

VIBSCANNER 2 EX

The new VibScanner 2 Ex is a next-generation, explosion protection system for quickly detecting machine vibration in hazardous work environments. Measuring simultaneously on three axes, the VibScanner 2 Ex sets the benchmark for fast and accurate measurements of machine, gear, and bearing issues.

This is the ultimate tool for fast and accurate machine vibration measurements. The VibScanner 2 Ex heightens efficiency and data quality. In just a quarter of the time of a standard data-collector, it precisely measures available data in three axes. Equipped with a triaxial sensor, it requires only one measurement point and the click of a button to begin collecting machine data.

This device is ideal for route-based maintenance jobs in environments where explosion protection standards are required. Its rugged magnetic foot of the triaxial sensor fits perfectly on the housing of any motor, pump, fan, or other rotating device, detecting vibration right near the source.

The VibScanner 2 Ex will diminish worries about finding the right measurement points at the machine. Because it features a Prüftechnik triaxial sensor, just one measurement point is required instead of three separate ones. This saves considerable time without sacrificing data quality. The “Triax-Effect” enables users to obtain measurements up to four times faster than the industry standard while achieving new levels of data quality.

ones. VibScanner 2 Ex thus saves considerable time without sacrificing data quality. The “Triax-Effect” enables obtaining measurements up to four times faster than the industry standard while achieving new levels of data quality.

This is the ultimate tool for fast and accurate machine vibration measurements. The VibScanner 2 Ex heightens efficiency and data quality. In just a quarter of the time of a standard data-collector, it precisely measures available data in three axes. Equipped with a triaxial sensor, it requires only one measurement point and the click of a button to begin collecting machine data.

This device is ideal for route-based maintenance jobs in environments where explosion protection standards are required. Its rugged magnetic foot of the triaxial sensor fits perfectly on the housing of any motor, pump, fan, or other rotating device, detecting vibration right near the source.

The VibScanner 2 Ex will diminish worries about finding the right measurement points at the machine. Because it features a Prüftechnik triaxial sensor, just one measurement point is required instead of three separate ones. This saves considerable time without sacrificing data quality. The “Triax-Effect” enables users to obtain measurements up to four times faster than the industry standard while achieving new levels of data quality.

ones. VibScanner 2 Ex thus saves considerable time without sacrificing data quality. The “Triax-Effect” enables obtaining measurements up to four times faster than the industry standard while achieving new levels of data quality.

VIBGUARD compact

VIBGUARD compact offers six measuring channels for continuous monitoring. It is perfectly suited for fast and highly dynamic equipment. In particular, the VIBGUARD compact meets the requirements of critical assets that are characterized by high availability, high aggregate values, complex drives and changing operating conditions.

Whether pre-installed in an IP65 compact housing or as a switch cabinet system module, the VIBGUARD compact is perfect for diagnostic condition monitoring of individual extruders, large fans, multiphase or vacuum pumps, turbocompressors, mill stands, or centrifuges.

All six measuring channels are designed as highly dynamic analog input channels and can be equipped with either standard ICP vibration sensors or with voltage input signals for process variables. They provide in depth diagnostic data such as time signals or envelope signals, and up to 6 characteristic values such as vibration characteristic or bearing condition.

The ‘Intelligent Event Recorder’ stores relevant results, fully automatically and continuously, providing the basis for comprehensive machine diagnostics. Its MQTT protocol enables the seamless integration to any IIoT manufacturing environment with highly secure data transfer

Whether pre-installed in an IP65 compact housing or as a switch cabinet system module, the VIBGUARD compact is perfect for diagnostic condition monitoring of individual extruders, large fans, multiphase or vacuum pumps, turbocompressors, mill stands, or centrifuges.

All six measuring channels are designed as highly dynamic analog input channels and can be equipped with either standard ICP vibration sensors or with voltage input signals for process variables. They provide in depth diagnostic data such as time signals or envelope signals, and up to 6 characteristic values such as vibration characteristic or bearing condition.

The ‘Intelligent Event Recorder’ stores relevant results, fully automatically and continuously, providing the basis for comprehensive machine diagnostics. Its MQTT protocol enables the seamless integration to any IIoT manufacturing environment with highly secure data transfer