Alignment & Vibration

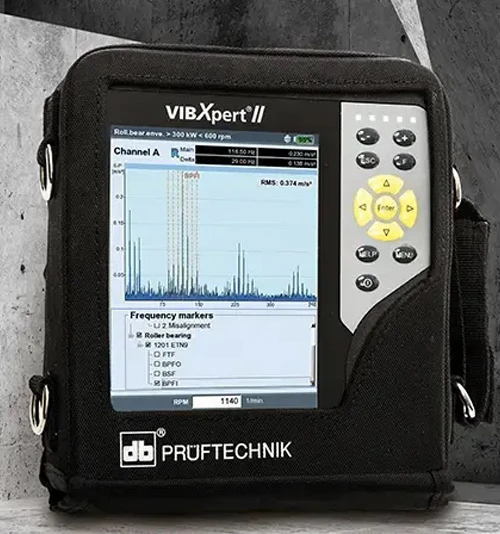

VIBXPERT II

The VIBXPERT II from PRUFTECHNIK is the mobile power package for fast and reliable recording and analysis of machine condition data. After a very short measuring time, the current machine status data is shown on the color display. The maintenance expert can analyze the data on site. From the recorded machine condition data, all values can be read from the various characteristic value modes that are important for an exact machine condition analysis.

The device is used directly on site at the machine, from the machine hall to the diesel generator of an oil tanker or from a bucket excavator to a hydroelectric turbine. The robust design enables both fast and complex interventions. Whether in clinically clean systems, or harsh industrial environments. VIBXPERT II sets the standard in mobile machine and plant condition monitoring.

In addition to reliable, fast, and highly effective data analysis, the VIBXPERT II can also be used for operational balancing. This makes the VIBXPERT II the most powerful and effective device in mobile condition monitoring. VIBXPERT II is compatible with PRUFTECHNIK’s own OMNITREND Center analysis software, enabling highly efficient and precise analysis results. Center analysis software, enabling highly efficient and precise analysis results.

The device is used directly on site at the machine, from the machine hall to the diesel generator of an oil tanker or from a bucket excavator to a hydroelectric turbine. The robust design enables both fast and complex interventions. Whether in clinically clean systems, or harsh industrial environments. VIBXPERT II sets the standard in mobile machine and plant condition monitoring.

In addition to reliable, fast, and highly effective data analysis, the VIBXPERT II can also be used for operational balancing. This makes the VIBXPERT II the most powerful and effective device in mobile condition monitoring. VIBXPERT II is compatible with PRUFTECHNIK’s own OMNITREND Center analysis software, enabling highly efficient and precise analysis results. Center analysis software, enabling highly efficient and precise analysis results.

Download

Produk Lainnya

VIBGUARD compact

VIBGUARD compact offers six measuring channels for continuous monitoring. It is perfectly suited for fast and highly dynamic equipment. In particular, the VIBGUARD compact meets the requirements of critical assets that are characterized by high availability, high aggregate values, complex drives and changing operating conditions.

Whether pre-installed in an IP65 compact housing or as a switch cabinet system module, the VIBGUARD compact is perfect for diagnostic condition monitoring of individual extruders, large fans, multiphase or vacuum pumps, turbocompressors, mill stands, or centrifuges.

All six measuring channels are designed as highly dynamic analog input channels and can be equipped with either standard ICP vibration sensors or with voltage input signals for process variables. They provide in depth diagnostic data such as time signals or envelope signals, and up to 6 characteristic values such as vibration characteristic or bearing condition.

The ‘Intelligent Event Recorder’ stores relevant results, fully automatically and continuously, providing the basis for comprehensive machine diagnostics. Its MQTT protocol enables the seamless integration to any IIoT manufacturing environment with highly secure data transfer

Whether pre-installed in an IP65 compact housing or as a switch cabinet system module, the VIBGUARD compact is perfect for diagnostic condition monitoring of individual extruders, large fans, multiphase or vacuum pumps, turbocompressors, mill stands, or centrifuges.

All six measuring channels are designed as highly dynamic analog input channels and can be equipped with either standard ICP vibration sensors or with voltage input signals for process variables. They provide in depth diagnostic data such as time signals or envelope signals, and up to 6 characteristic values such as vibration characteristic or bearing condition.

The ‘Intelligent Event Recorder’ stores relevant results, fully automatically and continuously, providing the basis for comprehensive machine diagnostics. Its MQTT protocol enables the seamless integration to any IIoT manufacturing environment with highly secure data transfer

RotAlign Touch Laser Shaft Alignment Tool

RotAlign Touch is the flagship laser alignment tool from Prüftechnik, a complete system that delivers maximum value and ROI for your alignment work.

• Superior single-laser technology eliminates pre-alignment & simplifies short-distance measurements

• NEW: Modular Platform allows your software & sensor package to evolve with you

• Automatically filter out bad data, from backlash to vibrations

• Readjust mid-measurement when out of range

• Advanced alignment tasks: In-Situ Cardan shaft, simultaneous coupling alignment, thermal growth, and more

• Superior single-laser technology eliminates pre-alignment & simplifies short-distance measurements

• NEW: Modular Platform allows your software & sensor package to evolve with you

• Automatically filter out bad data, from backlash to vibrations

• Readjust mid-measurement when out of range

• Advanced alignment tasks: In-Situ Cardan shaft, simultaneous coupling alignment, thermal growth, and more

VIBXPERT 3 Balancer

The VibXpert 3 Balancer is an advanced smart condition monitoring field balancing tool that enables users to quickly and effectively correct unbalance faults.

With the VibXpert 3 Balancer, users can:

• Increase the reliability of their machinery by reducing excessive machine vibration levels

• Improve safety by reducing potential equipment hazards

• Improve uptime by promptly identifying and correcting unbalance

• Help meet industry standards and regulatory compliance requirements

• Improve energy efficiency of rotating machinery, providing cost savings

• Maximize the efficiency, quality, and accuracy of field balancing jobs

The result is extended peak operating asset performance, more effective resource use, and increased business value from operations.

Unbalance, resulting from uneven mass distribution around a rotational axis is the leading cause of unplanned downtime and costly damage.

Today, machines operate at variable speeds, sometimes near their engineered capacity, increasing the risk of resonant vibration. Balanced machines mitigate this risk. The VibXpert 3 Balancer offers a highly efficient and user-centric experience, faster balancing results with better insights, and enhanced fault detection on rotating assets.

Machine templates

It boasts an interactive user interface with preconfigured and customizable machine templates, reducing the complexity of the balancing process.

Modern data processing

Its modern data processing capability, optimized software-based calculations from raw sensor data offers faster measurements, complete insights during balancing (including overall vibration levels, FFT spectra, phase, and time waveform).

6-channel measurements

VibXpert 3 Balancer enhances fault detection through synchronous 6-channel measurement, enabling users to minimize overall vibration levels simultaneously across all machine measurement points

Enhanced balancing reports

Balancing reports encompassing all necessary information for users, including overall vibration levels, spectral graphs, polar plots, and machinery details, among others.

With the VibXpert 3 Balancer, users can:

• Increase the reliability of their machinery by reducing excessive machine vibration levels

• Improve safety by reducing potential equipment hazards

• Improve uptime by promptly identifying and correcting unbalance

• Help meet industry standards and regulatory compliance requirements

• Improve energy efficiency of rotating machinery, providing cost savings

• Maximize the efficiency, quality, and accuracy of field balancing jobs

The result is extended peak operating asset performance, more effective resource use, and increased business value from operations.

Unbalance, resulting from uneven mass distribution around a rotational axis is the leading cause of unplanned downtime and costly damage.

Today, machines operate at variable speeds, sometimes near their engineered capacity, increasing the risk of resonant vibration. Balanced machines mitigate this risk. The VibXpert 3 Balancer offers a highly efficient and user-centric experience, faster balancing results with better insights, and enhanced fault detection on rotating assets.

Machine templates

It boasts an interactive user interface with preconfigured and customizable machine templates, reducing the complexity of the balancing process.

Modern data processing

Its modern data processing capability, optimized software-based calculations from raw sensor data offers faster measurements, complete insights during balancing (including overall vibration levels, FFT spectra, phase, and time waveform).

6-channel measurements

VibXpert 3 Balancer enhances fault detection through synchronous 6-channel measurement, enabling users to minimize overall vibration levels simultaneously across all machine measurement points

Enhanced balancing reports

Balancing reports encompassing all necessary information for users, including overall vibration levels, spectral graphs, polar plots, and machinery details, among others.

Fluke 805 Vibration Meter

• Reliable, repeatable, accurate device for checking bearings and overall vibration

• Features innovative sensor design that minimizes measurement variations caused by device angle or contact pressure

• Provides consistent data quality at both low and high frequency ranges

• Offers four-level severity scale to assess urgency of problems and bearing condition

• Features innovative sensor design that minimizes measurement variations caused by device angle or contact pressure

• Provides consistent data quality at both low and high frequency ranges

• Offers four-level severity scale to assess urgency of problems and bearing condition